High Pressure Hydro Jetting Machines

We have leveraged for over 25 years on more than 3000 Hydro Jetting Machines to clean Heat Exchanger and Evaporator Tubes to our loyal customer base to provide with

-

Effective and Efficient High Pressure Hydro Jetting Machine

-

Low Life Cycle Costs

-

High Reliability and Availability

As an expert through our standardised and methodical procedures, a highly precisive well-established Hydro Jetting Pumps are available to clean the contamination deposits from your Heat Exchanger, Condenser Tubes, Calendria and Evaporator, Boiler Tubes thoroughly, with up to 1400 Bar (20,000 PSI) Pressure. A full load precision testing is conducted on every equipment in a dust free setting that results in solutions that maximise simplicity, flexibility, and efficiency.

We are sure you would want to save your valuable time and operating cost with an affordable purchase cost.

With products available for every solution for every industry, PressureJet offers you solid guarantee of most dependable Water Jetting Machines backed by the confidence of the manufacturing capability of World's Most Accurate and Precision Machines.

We hereby announce that we own India’s largest High Pressure Plunger Pump manufacturing facility with more than 70,000 sq.ft. area.

Contact us and we will evaluate the cost savings and the operational efficiency you can achieve. We will call you as well for a live demonstration of the machinery and state-of-the-art manufacturing facility.

Support and Innovation

Would you like us to evaluate how you can augment operational efficiency of your plant and potential cost savings?

High quality and low maintenance cost of PressureJet's Hydro Jetting Equipment will surely boost your PROFIT and increase operational efficiency of your plant!

Applications of Hydro Jetting M/Cs

Custom Systems

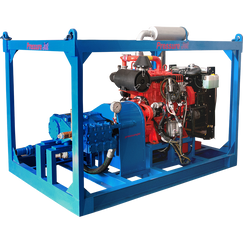

1000 Bar to 1400 Bar High Pressure Hydro Jetting Machines

Product Specifications

Driver Type:- Electric Motor Driven, Diesel Engine Driven

Electric Motor Options:- Flame Proof Motor, Non-Flame Proof Motor, Hydraulic Motor, Energy Efficient Motor

Mounting Option:- Trolley Mounted, Skid Mounted

RPM:- For 50 Hz - 1500 RPM and 60 Hz - 1800 RPM

Power Supply:- 3 Phase

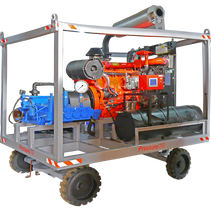

750 Bar Hydro Jetting Machines

Product Specifications

Driver Type:- Electric Motor Driven, Diesel Engine Driven

Electric Motor Options:- Flame Proof Motor, Non-Flame Proof Motor, Hydraulic Motor, Energy Efficient Motor

Mounting Option:- Trolley Mounted, Skid Mounted

RPM:- For 50 Hz - 1500 RPM and 60 Hz - 1800 RPM

Power Supply:- 3 Phase

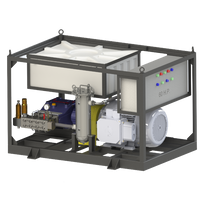

600 Bar Hydro Jetting Equipments

Product Specifications

Driver Type:- Electric Motor Driven, Diesel Engine Driven

Electric Motor Options:- Flame Proof Motor, Non-Flame Proof Motor, Hydraulic Motor, Energy Efficient Motor

Mounting Option:- Trolley Mounted, Skid Mounted

RPM:- For 50 Hz - 1500 RPM and 60 Hz - 1800 RPM

Power Supply:- 3 Phase

250 Bar to 500 Bar Hydro Jetting Machines

Product Specifications

Driver Type:- Electric Motor Driven, Diesel Engine Driven

Electric Motor Options:- Flame Proof Motor, Non-Flame Proof Motor, Hydraulic Motor, Energy Efficient Motor

Mounting Option:- Trolley Mounted, Skid Mounted

Power Supply:- 3 Phase

50 Hz (1450 RPM)

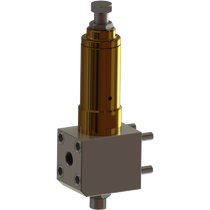

Accessories of Hydro Jetting M/Cs

Frequently Asked Questions

Clients

Performance Certificates

Started in 1996, PressureJet Systems Pvt. Ltd. has been committed to provide the best-in-class quality products and services to its 5000+ valued clients across the globe. With 25 years of experience and dedicated team to help customers reach their highest potential, PressureJet has surpassed the standards set by other firms in the Indian subcontinent.

PressureJet offers the widest range of high-pressure triplex plunger pumps ranging from 60 to 1400 bar. This product line is intended to meet the demands of the vast majority of clients across a wide range of industries and applications like Hydro Blasting, Hydro Jetting, Industrial High Pressure Cleaning, Hydrostatic Pressure Testing, Sewer Jetting, UHP Fire Fighting, Paint and Rust Removal are just a few of the services we provide.

PressureJet’s core belief is to offer our clients with high-quality and durable products at affordable prices. Our aim is to invest in quality assurance which will decrease the product's overall price, rather than going the other way. To achieve the standards which are expected, each PressureJet product goes through 694 parameter checks and 257 precision-calibrated testing & measurement equipment to make sure that every product which is delivered is of the utmost quality which is assured by PressureJet to each of their clients.

Unlike other manufacturers, at PressureJet, we don't want you to just take our word for it. Words hardly scratch the surface of our capabilities and accomplishments. The standards and thorough checks which our products go through make sure that every product which is delivered is of supreme quality and helps our customers to reach their intended goals.

About PressureJet

25+

Years of Expertise

5000+

Globally Happy Customers

80%

In-House Manufacturing

90%

Parts Inspected on CMM

50+

Experienced

Engineers' Team

What Our Clients Say

Contact

Head Office

Quick Enquiry

21- 24, Panchratna Industrial Estate,

Near Oad Village, Paldi Kankaj, Pirana, Ahmedabad, Gujarat, 382427, India

Tel: +91 937-502-2359

Service

Tel: +91 823-803-1988

Get a quote: +91 937-502-2359